Features

Features and Benefits

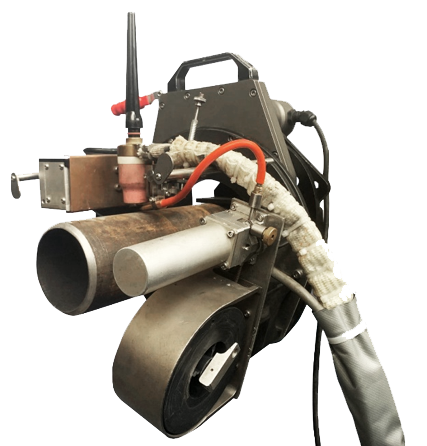

- The welding head travelling and wire feeding are drove by comstant torque motor. Meanwhile, in the condition of ensuring wire feeding stability, the encoder is equipped to keep welding stable for both downward welding and upward welding.

- The welding head can calculate the travelling position according to the rotation angle, and can provide accurate position signal in the process of all-position welding, which greatly improves the quality of all-position welding.

- Wire feeding angle setting device can be applied to adjust wire feeding tip flexibly in all directions.

- The welding head can be customized according to pipe diameter, which is suitable for several kinds of pipe diameter, 30mm – 168mm

- Matching with WZM400 power source