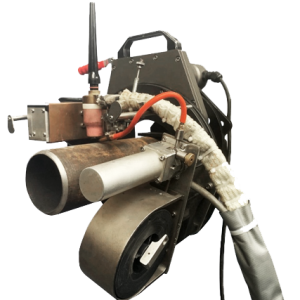

Features

Features and Benefits :

- Free from manual intervention: fully automated welding

- Free from teaching and programming: directly import the CAD drawings and transform them into the coordinates

- Free from welding distortion: freely marking the welding procedure during tube-to-tubesheet welding

- Ensured qualification rate of welding seam: the workpiece processing deviation is compensated through visual detection

- Quick locating: 6-axis robot and the locating time is less than 2 seconds