Features

Features and Benefits (WZM200 Power Source):

- Small and light welding head: easy operation with no need of manual interference

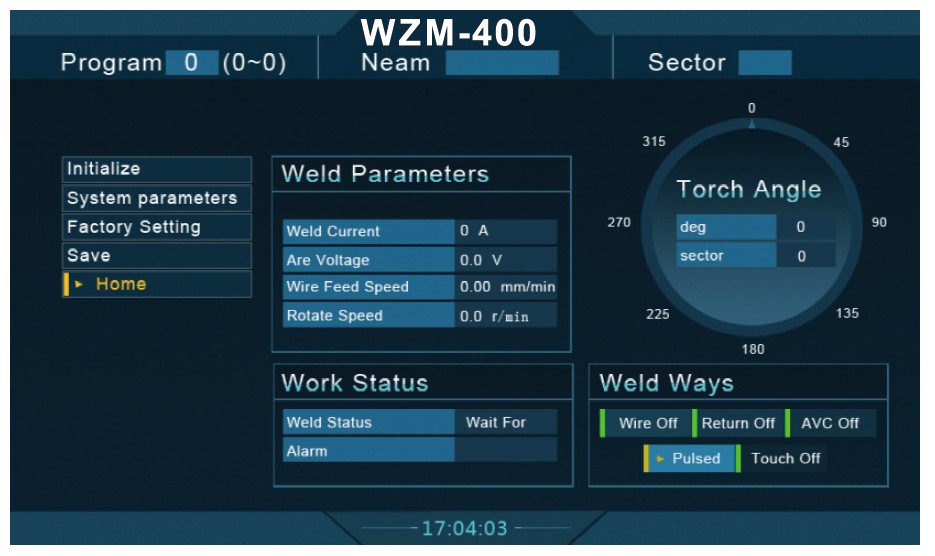

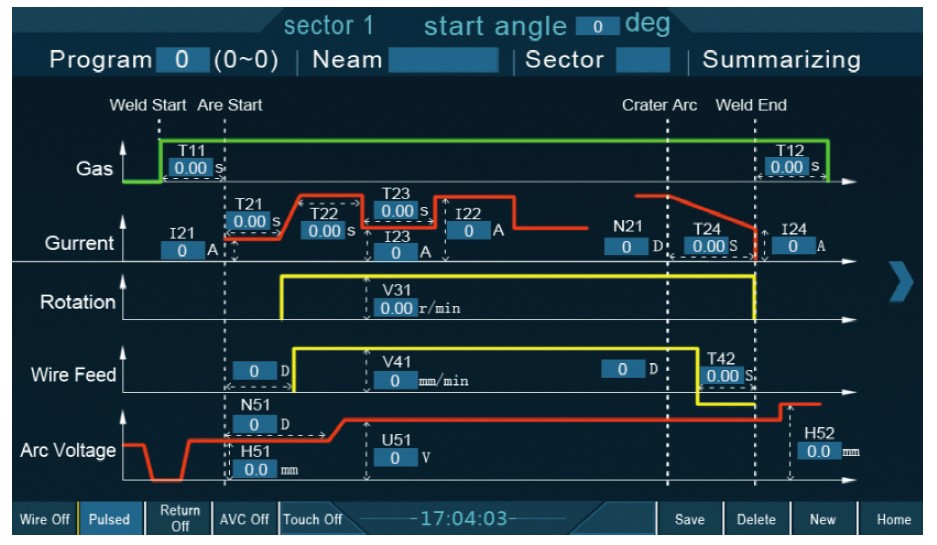

- 7-inch touch screen: friendly and visualized programming interface with simple and easy operating method

- Long-life motor: high-quality DC core-less servo motor enjoys stable performance and long service life

- Unlimited rotation: not entangled by water hoses, electric wires, and gas hoses

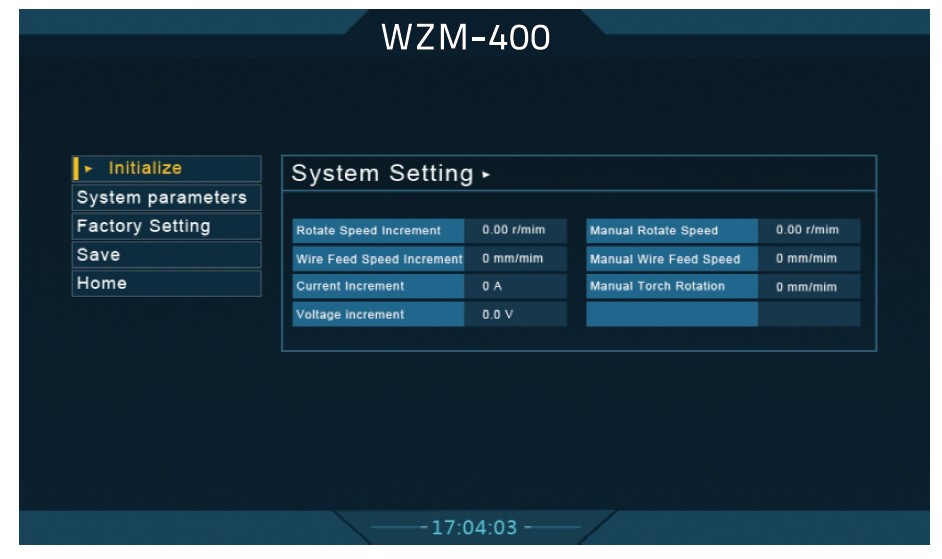

- Save and recall 60 sets of parameters: up to 60 sets of parameters can be saved and recalled, and one process can be divided into up to 16 sectors

- Abundant expert database: the welding programs can be generated automatically according to different pipe diameters and wall thickness

- Built-in printer: automatically print welding parameters for convenient filing

Features and Benefits:

- No requirements for welder skills: small size, light weight, and simple operation

- Safe and reliable: flexible automatic centering fixture, and accurate positioning

- High weld quality: the closed-type welding

- Free from intertwined trouble: infinite rotation device for water hose, power cable, and gas hose

- Water cooling and high duty cycle

- Convenient for fast welding: common function keys on the welding head