Features

Features and Benefits (WZM400 Power Source)

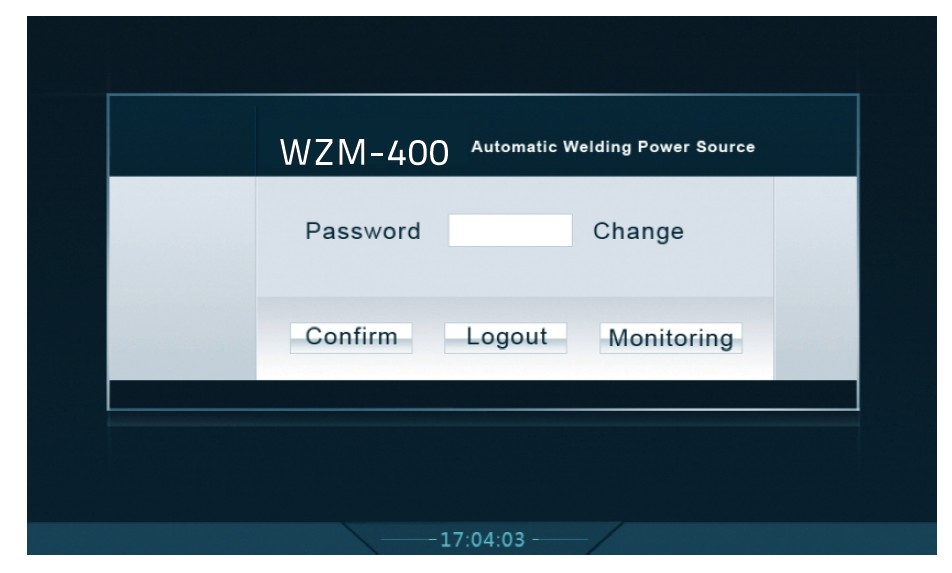

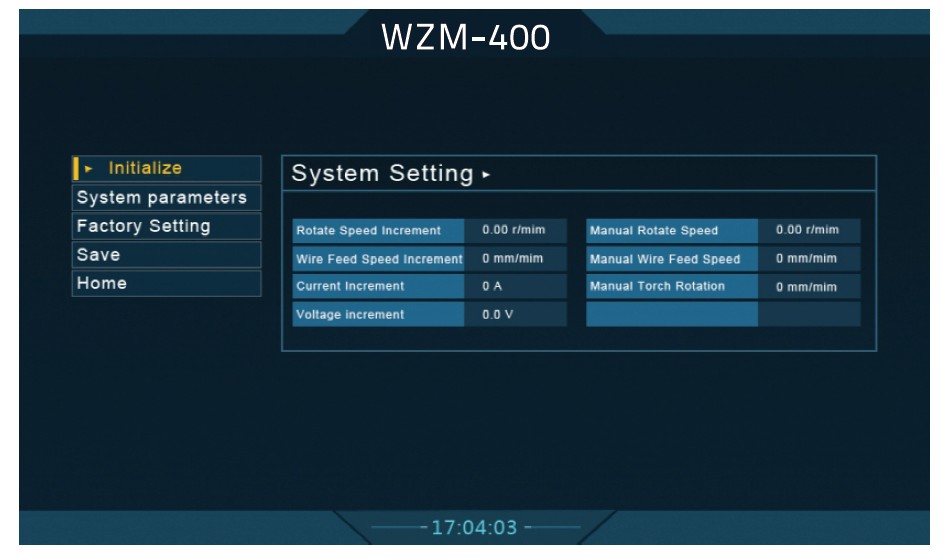

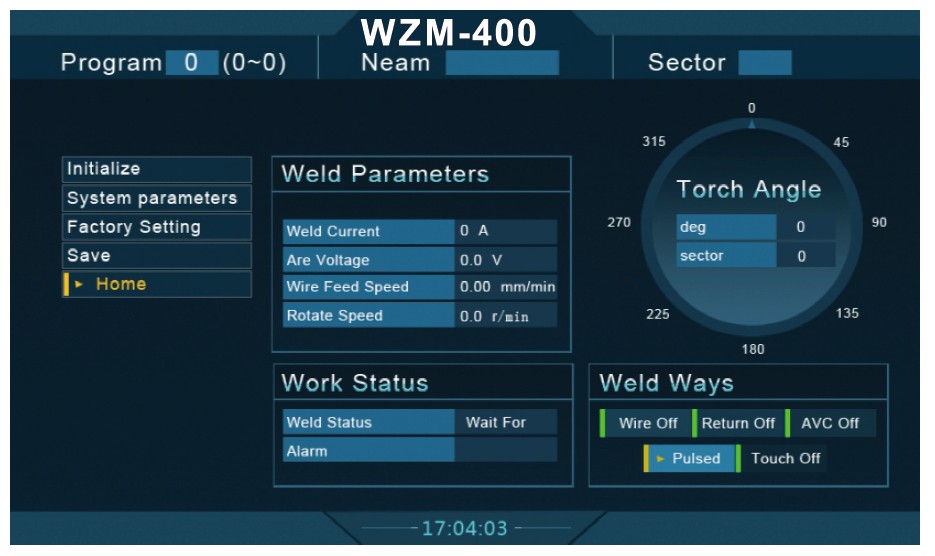

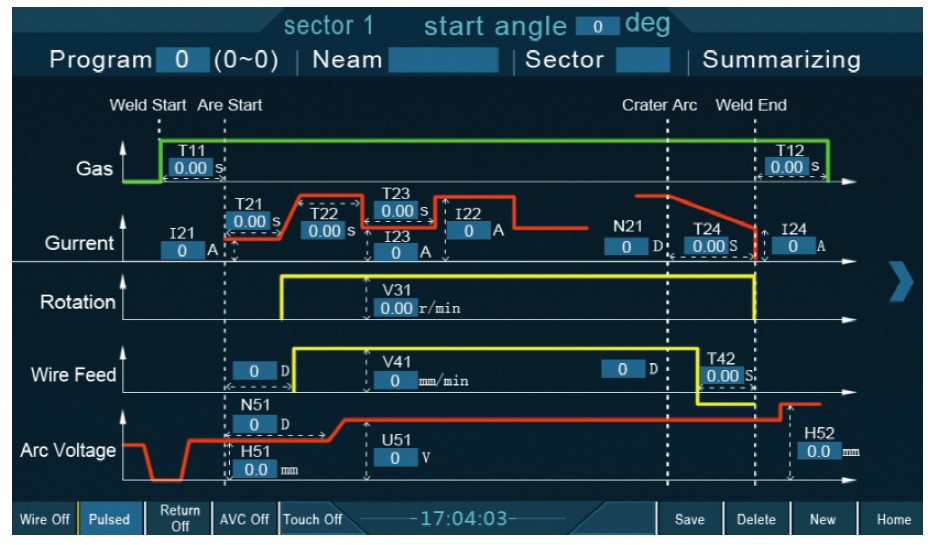

- Fine control of welding process: programmable automatic digital system

- Perfect control of the welding process: real-time fine adjustment of welding parameters through the remote control box

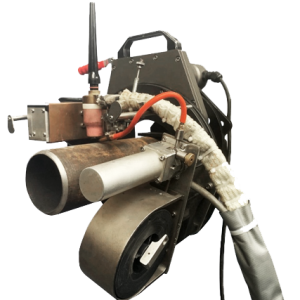

- Easy to move: highly integrated design and compact structure

- Multiple controls: CC or pulsed current output, rotation control, wire feeding control, shielding gas control, arc length control, and horizontal oscillation control

- Safe and reliable: multiple protections against water shortage and overheating; emergency stop and other protection functions

- Easy to operate: lower requirements for welder’s skill

- Excellent welding performance and appearance

- Free from intertwined trouble: infinite rotation device for liner, water hose, power cable, and gas hose