Features

Features and Benefits (WZM400 Power Source):

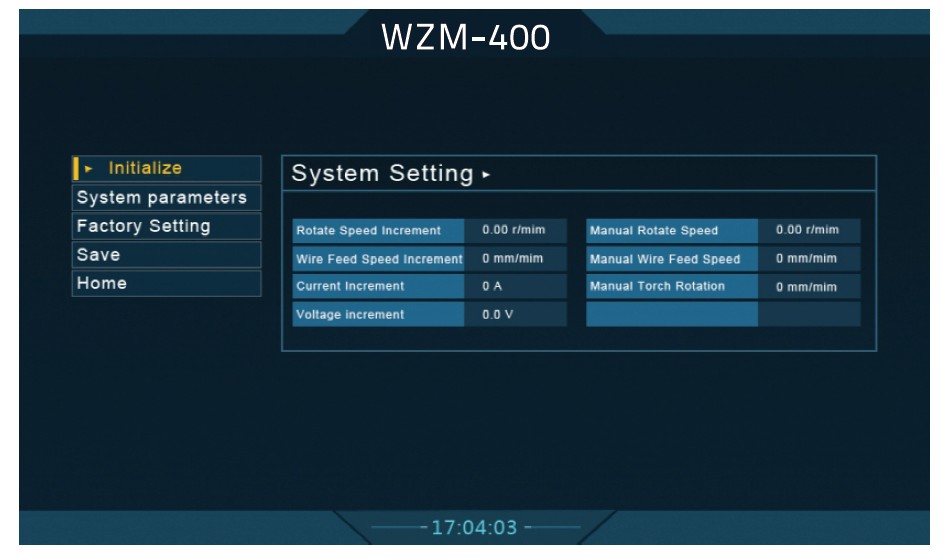

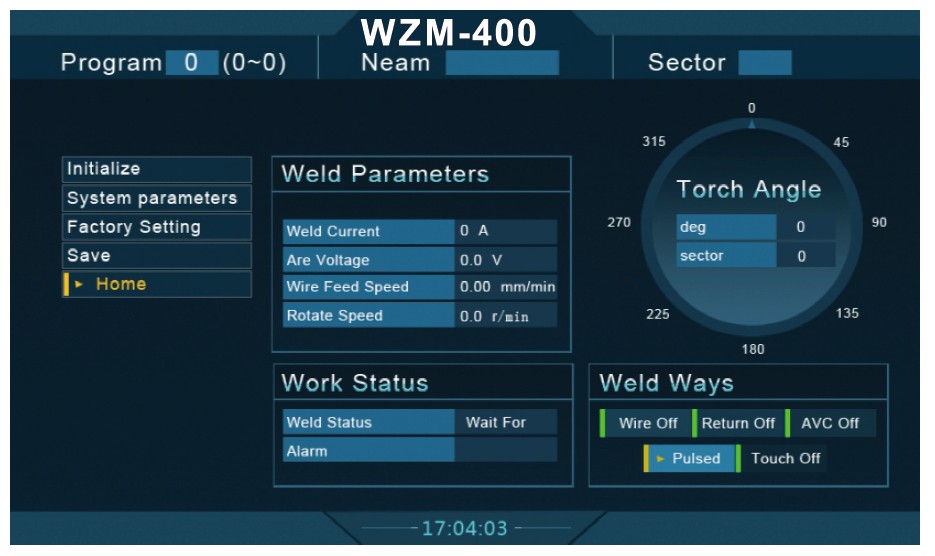

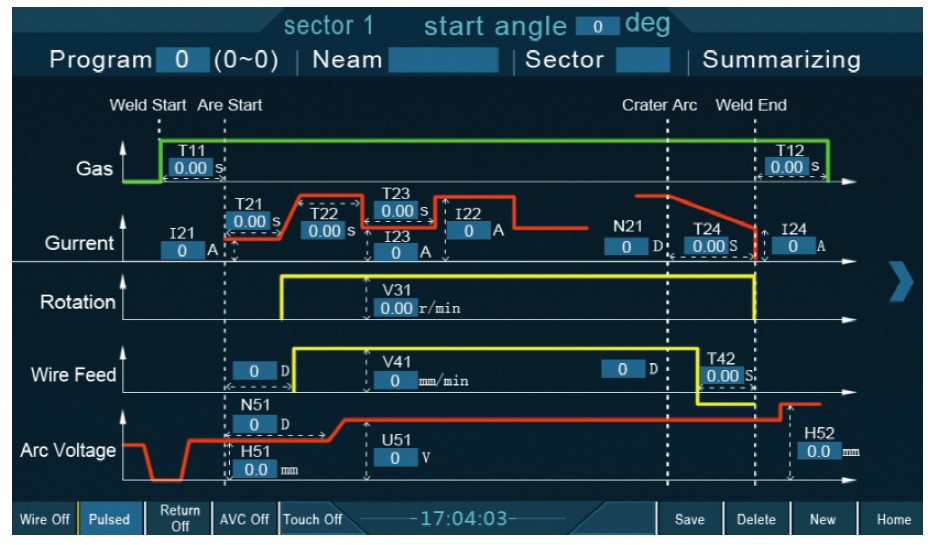

- Programmable automatic digital system,fine control of welding process.

- Real-time fine tuning welding parameters on remote control box, perfect control of welding process.

- Highly integrated design, compact structure, easy to move.

- Functions:CC or pulse current output/Rotation control/ Wire feeding control/ Protection gas control, etc.

- Water shortage, overheating, emergency stop and other protection functions, safe and reliable.

- Small size, light weight, simple operation, zero requirement for welder skill

- Flexible and accurate positioning, safe and reliable

- Closed-type welding ensures welding seam quality

- Infinite rotation structure avoids water, power, and gas winding

- Water cooled, high duty cycle